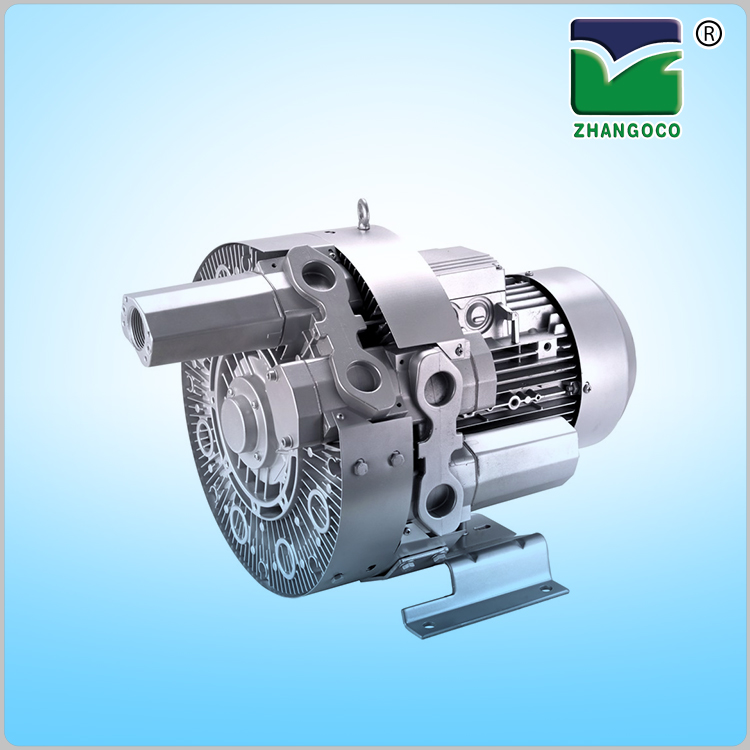

Side flow fan, also known as high-pressure fan or air ring vacuum pump. The impeller is directly installed on the motor rotor, which is completely contactless compression.

working principle:

The impeller is directly installed on the motor rotor, which is completely contactless compression. Due to the installation of the pump shaft outside the compression chamber, the reliability of the machine's Z-large operation can be ensured even when working under Z-large pressure differentials.

The gas is sucked in through the suction port 1, and when it enters the side channel 2, the rotating impeller 3 gives the gas a velocity in the direction of rotation. At the same time, the centrifugal force on the blades accelerates the gas outward and increases the pressure. As the rotation progresses, the kinetic energy of the gas increases, causing the gas pressure along the side channel to further increase. As the side channel narrows at the outlet, gas is squeezed out of the blades and discharged from the pump body through the outlet muffler 4.

This type of fan is generally referred to as an air ring vacuum pump, vortex vacuum pump, vortex vacuum pump, oil-free vacuum pump, etc. in foreign countries. In China,

Due to their widespread use in aquaculture, we commonly refer to them as: aerator pump, vortex pump, vortex pump, air pump, etc. In Taiwan and other regions of our country, they are called high-pressure blowers, high-pressure suction blowers, blowers, ring blowers, blower motors, etc.

In the category of fans, it is called a side flow fan.

Due to its low operating noise, especially the greater the power, the more noticeable it becomes

Exhibition High~Alibaba Customer Service

Exhibition High~Alibaba Customer Service