Installation instructions:

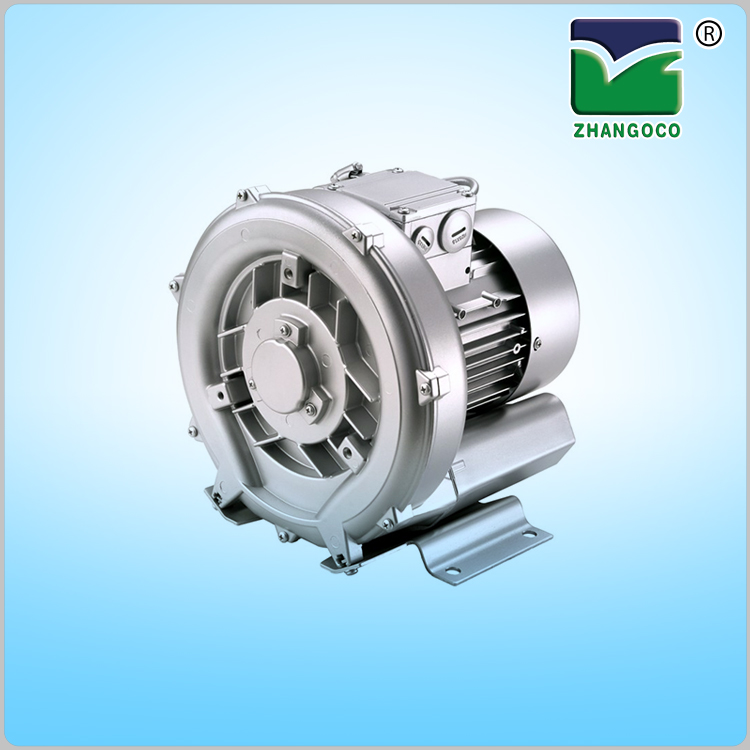

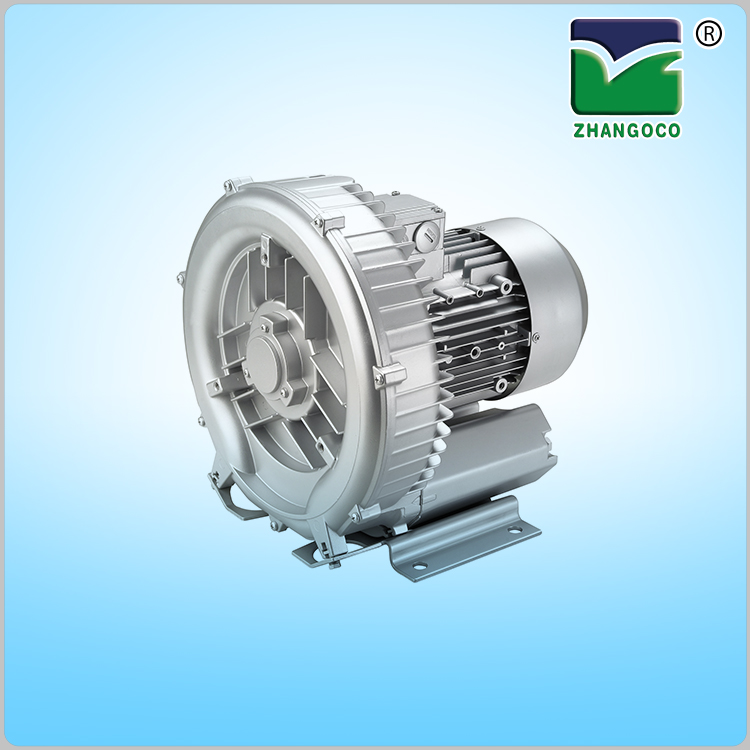

1、Vortex blowerIt should be placed in a relatively stable place, and the surrounding environment should be clean, dry, and well ventilated.

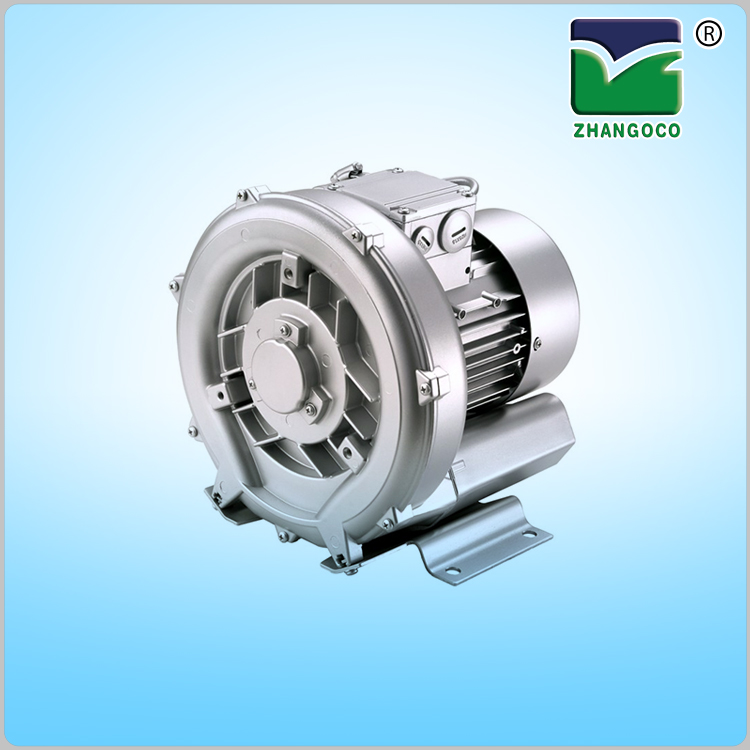

2. The rotation direction of the impeller of the vortex fan must be consistent with the direction indicated by the arrow on the fan casing.

3. When the high-pressure vortex fan is working, the working pressure should not exceed 8kPa to avoid excessive heat generated by the fan and damage to the air pump caused by motor overcurrent.

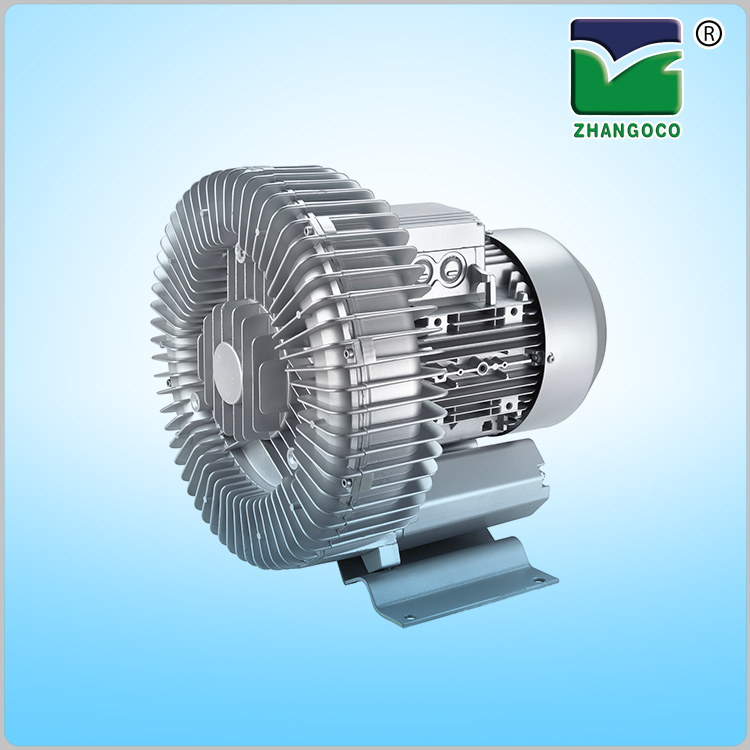

4. Except for the two bearings of the motor rotor, there is no direct contact friction in other parts of the vortex fan. The installation method of bearings for this fan is mainly divided into two categories. The bearings on the first type of air pump are installed in the pump body between the motor base and the impeller, and this type of air pump does not require lubricating grease during normal operation. The bearings on the second type of air pump end are installed in the middle of the pump cover, and the bearings on this type of air pump end should be regularly lubricated with grease (7018 high-speed grease). Once a month, for air pumps that work continuously in three shifts, the refueling frequency should be increased. The maintenance and upkeep of the bearings on the fan end of this type of air pump motor shall be in accordance with the first type of air pump.

5. The filter screens and silencing devices at both ends of the vortex air pump should be cleaned in a timely manner according to the situation to avoid blockage and affect use.

6. The external connection of the inlet and outlet of the vortex air pump must be made using flexible hoses (such as rubber hoses or plastic spring hoses).

7. Replacement of bearings for vortex air pump: The replacement of bearings must be carried out by personnel familiar with repair work. First loosen the screws on the pump cover, and then disassemble the parts one by one according to the order shown in the diagram. The disassembled parts should be cleaned, and then assembled in reverse order. When disassembling, do not forcefully pry the impeller. Use a dedicated roller to remove it, and do not miss the adjusting gasket to avoid affecting the clearance that has been adjusted before leaving the factory.

8. The high-pressure vortex air pump strictly prohibits solids, liquids, and corrosive gases from entering the pump body.

Exhibition High~Alibaba Customer Service

Exhibition High~Alibaba Customer Service