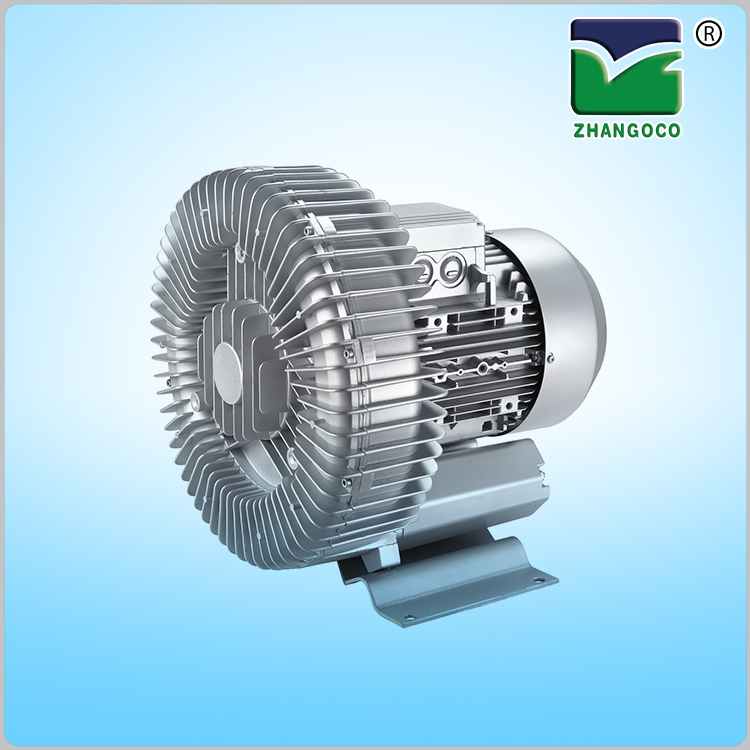

Wind knives are widely used in the industrial field for blowing water and dust removal, such as blowing off dust and moisture on flat surfaces such as steel plates and aluminum alloy profiles, blowing off moisture on the surface of beverage bottles, packaging cans, and other bottle bodies, blowing off impurities, dust, residue, moisture on product surfaces, and cleaning conveyor belts. Under the condition of compressed air supply, the air knife can meet these applications.

The working principle of the Zhangao Wind Knife Super Wind Knife is that compressed air enters the wind knife and is blown out at high speed with a thin airflow sheet with a thickness of only 0.05 millimeters on one side. Through the principle of the Coanda effect and the special geometric shape of the wind blade, this thin film wind curtain can withstand 30-40 times the ambient air, forming a thin, high-intensity, and high airflow impact wind curtain. Wind knives are divided into two types based on their working modes: standard wind knives and super wind knives. The wind curtain of the standard wind knife deflects 90 degrees and blows out, while the wind curtain of the super wind knife blows out horizontally.

Characteristics of Wind Knife

1. The manufacturing material of the wind blade is aluminum alloy or stainless steel. The aluminum alloy wind blade undergoes electroplating treatment in the manufacturing process, and its service life is much longer than other similar products. The stainless steel wind blade can be used in high temperature and high corrosion environments;

2. The "full airflow" design means that the width of the wind blade is exactly the same as the width of the air curtain blown out by the wind blade. The back of the wind blade has installation and connection screw holes, which can be combined according to the required length;

3. The wind knife can drain 40 times more ambient air, with a gas consumption of only 15% compared to traditional blowing tubes;

4. There are no worn parts inside the wind blade, and the internal gasket is made of stainless steel material, with a service life of over 10 years;

5. Powered by compressed air, no electricity required, suitable for use in explosion-proof environments. The wind knife application generates a powerful air curtain, which can be used for various blowing and air cooling applications, such as:

1. Automotive industry: used for blowing away additional water, coolant, dust, debris, etc. in manufacturing, as well as blowing air for cooling, drying, and dust removal before painting steel plates.

2. Electronics industry: Electronic circuit boards are quickly dried before assembly.

3. Beverage canning and bottle making: Before labeling, inkjet printing, or packaging beverage bottles, blow off the moisture and attachments from the bottle mouth or body.

4. Chemical industry: Before labeling or packaging, blow off surface chemicals or moisture.

5. Food and medicine: Blow off moisture and attachments before manufacturing or packaging, or remove dust from openings and bags before packaging.

6. Metal industry: blowing coolant or other liquids from the surface of metals. Dry or cool the surface before polishing, electroplating, and painting processes.

7. Rubber and plastic material industry: blow off dust or debris on the surface of products. Dry before extrusion or injection. After injection molding, the product cools down.

8. Printing (inkjet): Inkjet printing, blowing away dust, debris, and water vapor before printing, or used for rapid drying of ink.

Exhibition High~Alibaba Customer Service

Exhibition High~Alibaba Customer Service