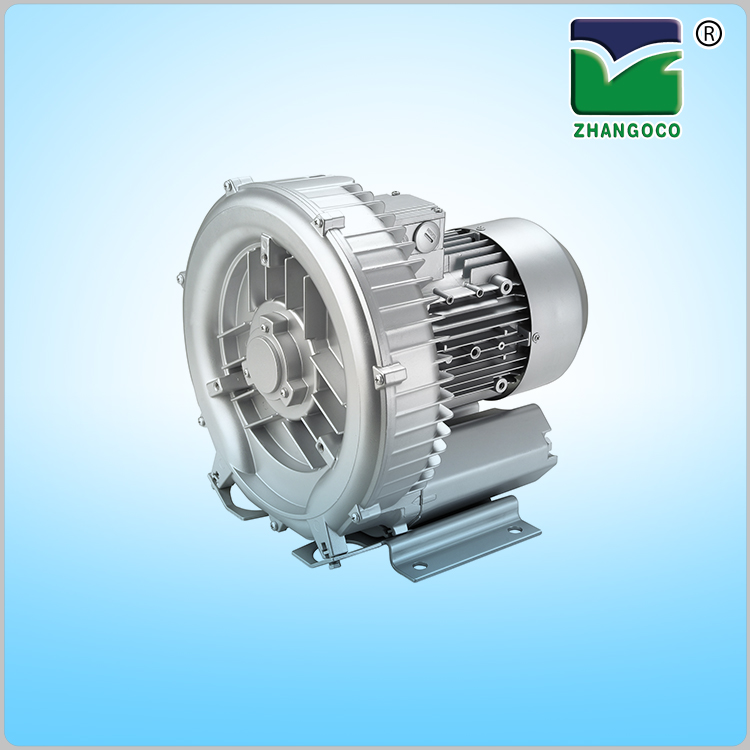

Principle and characteristics of aeration fan

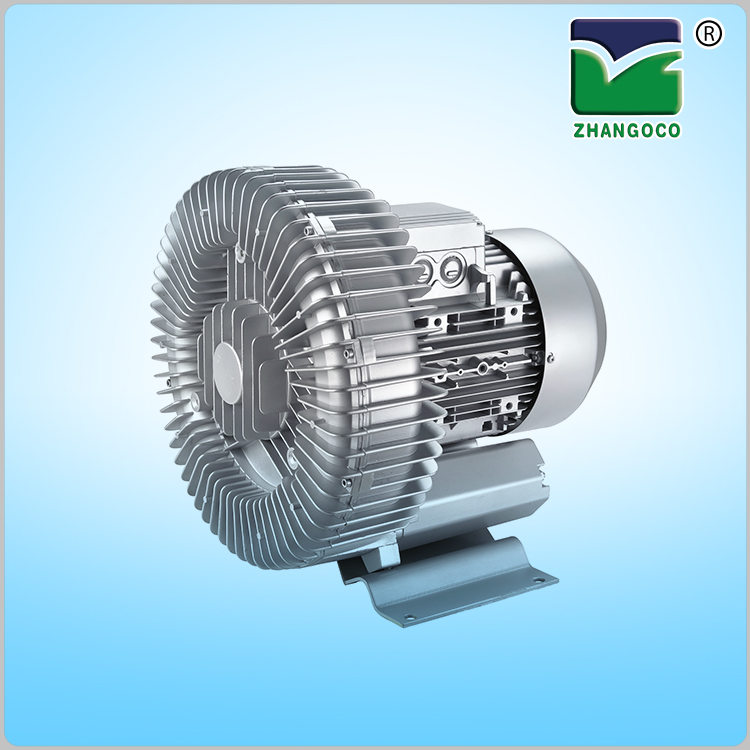

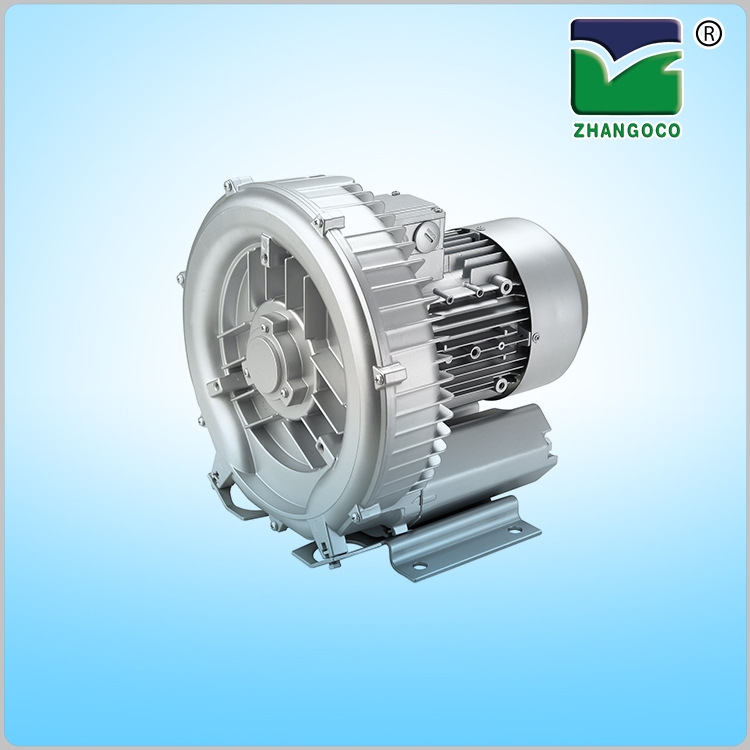

The impeller of a vortex air pump is composed of several blades, similar to the impeller of a large gas turbine. Air in the middle of the impeller blades

Under the action of centrifugal force, it moves towards the edge of the impeller, where air enters the annular cavity of the pump body and circulates again in the same way from the starting point of the blades. The circulating airflow generated by the rotation of the impeller leaves the air pump with extremely high energy for use. Air pump, small in size, light in weight, low in noise, delivering air source without water or oil.

Scope of Application of Aeration Fan

edit

Vortex air pump is a dual-purpose ventilation air source mainly used for blowing air; Paper cutting machine, combustion oxygen reduction machine, filter forming machine, electroplating tank mixing, atomization dryer, fish farming and oxygenation, water treatment explosion gas, screen printing machine, photographic plate machine, automatic lightweight feeding machine, liquid filling machine, powder filling machine, welding equipment, film machinery, paper conveying, cleaning of dry cleaning clothes, air dust removal, dry bottle, gas conveying, feeding, collection, etc;.

Calculation of air volume

edit

Calculation of air volume for vortex high-pressure fan:

Air volume (Q): The so-called air volume (also known as volumetric flow rate) refers to the velocity of the airflow passing through the cross-sectional area of the air duct, which is generally expressed using the following formula:

Q=60VA

Q(风量)=m3/min

V(风速)=m/sec

A (cross-sectional area)=m2

Usage and maintenance

edit

1. The vortex air pump should be placed in a relatively stable place, and the surrounding environment should be clean, dry, and ventilated.

2. The rotation direction of the impeller of the vortex air pump must be consistent with the direction indicated by the arrow on the fan casing.

When the vortex air pump is working, the working pressure should not exceed 8kPa to avoid excessive heat generation and motor overcurrent that may cause damage to the air pump.

4. It is strictly prohibited for solids, liquids, and corrosive gases to enter the pump body of the vortex air pump.

5. The filter screens and silencing devices at both ends of the vortex air pump should be cleaned in a timely manner according to the situation to avoid blockage and affect use.

6. The external connection of the inlet and outlet of the vortex air pump must be made using flexible hoses (such as rubber hoses or plastic spring hoses).

7. Replacement of bearings for vortex air pump: The replacement of bearings must be carried out by personnel familiar with repair work. First loosen the screws on the pump cover, and then disassemble the parts one by one according to the order shown in the diagram. The disassembled parts should be cleaned, and then assembled in reverse order. When disassembling, do not forcefully pry the impeller. Use a dedicated roller to remove it, and do not miss the adjusting gasket to avoid affecting the clearance that has been adjusted before leaving the factory.

8. Except for the two bearings of the motor rotor, there is no direct contact friction in other parts of the vortex air pump. The installation method of bearings for this air pump is mainly divided into two categories. The bearing at the end of the class air pump is installed in the pump body between the motor base and the impeller, and this type of air pump does not need to be lubricated normally. The bearings on the second type of air pump end are installed in the middle of the pump cover, and the bearings on this type of air pump end should be regularly lubricated with grease (7018 high-speed grease). Once a month, for air pumps that work continuously in three shifts, the refueling frequency should be increased. The maintenance and upkeep of the bearings on the motor and fan end of this type of air pump are classified according to the type of air pump.

Exhibition High~Alibaba Customer Service

Exhibition High~Alibaba Customer Service