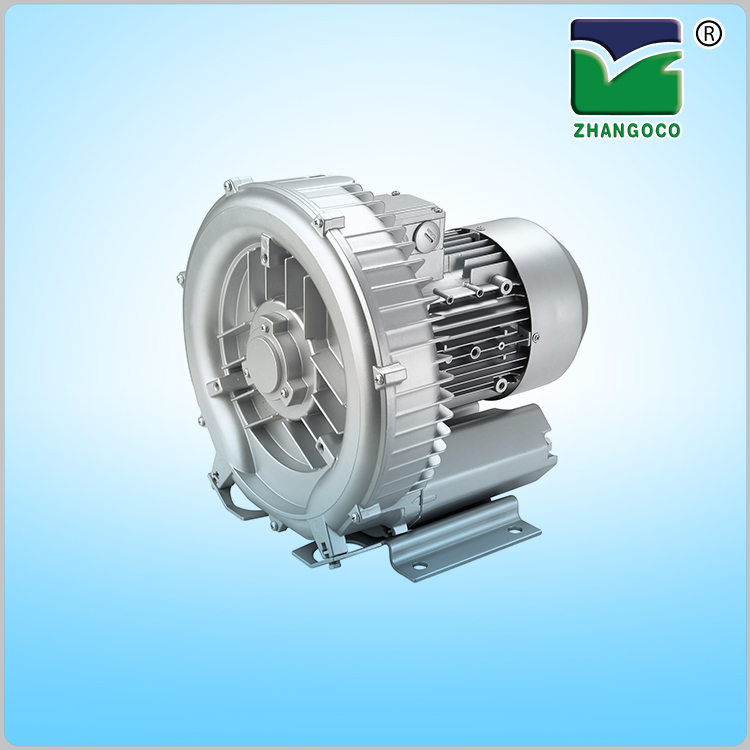

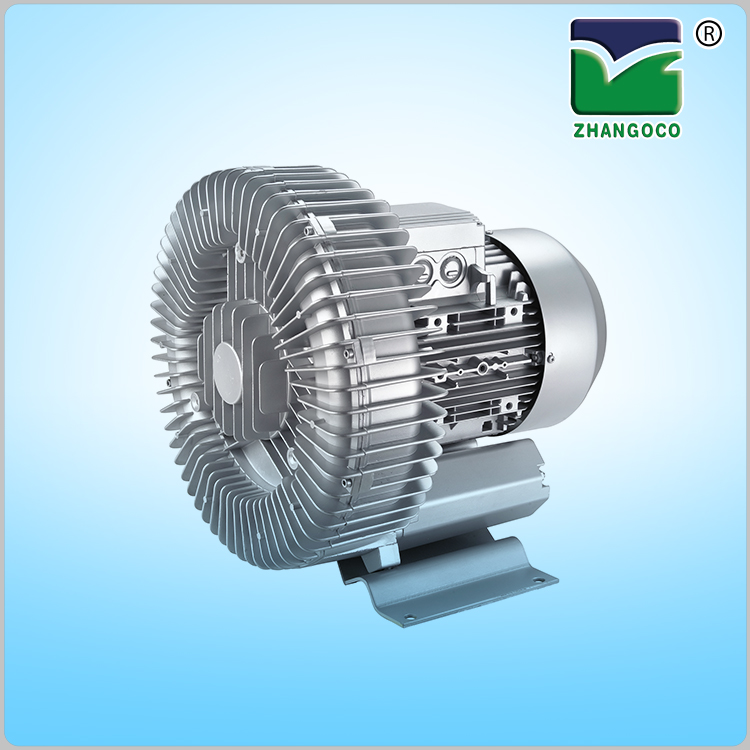

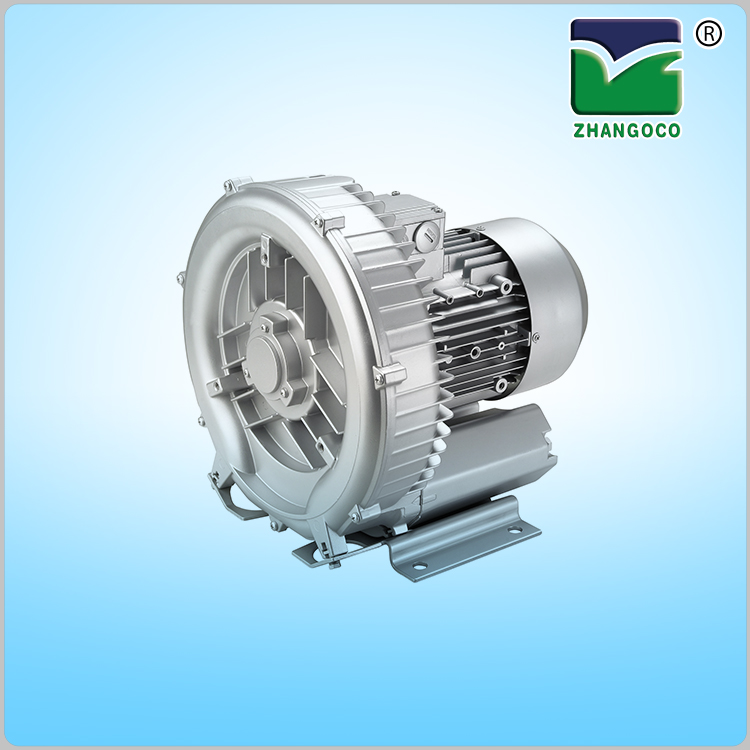

Recently, many friends have inquired about us online:High pressure centrifugal fanCan you repair the worn impeller?

We are also quite speechless. We are a manufacturer of fans, not a fan repair shop.

Today, the editor searched online for some information about fan impeller maintenance and would like to share it with everyone:centrifugal fan

If the impeller blades of the centrifugal fan wear out large gaps or the fan blades wear severely beyond the tolerance, it cannot continue to operate.

If the user has an electrician or welder on site.

It is possible to carry out some repairs on site without dismantling the impeller.

The specific method is as follows:

Firstly, it is necessary to draw a cutting line on the blade based on the wear of the impeller on site, and carefully cut off all the parts of the blade that have become thinner due to wear.

Use a polishing machine to clean the area around the incision, remove welding slag, burrs, and other debris to facilitate the next welding process.

Then, based on the size of the cut blades, cut the blade spare parts on the steel plate, and choose a steel plate of the same material as the wind turbine for operation.

The three sides of the spare steel plate in contact with the impeller should be polished with a single-sided groove.

Welding can be done using methods such as cold welding and direct current reverse connection.

During welding, it is important to ensure uniformity.

Carefully clean the back with an angle grinder, confirm there are no defects, and repeat the above steps to weld the back completely.

After welding, the coating should be carefully removed and must be completely removed.

Before balancing the impeller, it is necessary to carefully clean all the impellers, including any skin or dust accumulation on them.

After the centrifugal fan is repaired, it can run smoothly for a period of time with an operating rate of over 95%, and then the centrifugal fan can be considered to have achieved normal operation.

Exhibition High~Alibaba Customer Service

Exhibition High~Alibaba Customer Service